Oscillating cutters have revolutionized various industries by providing precise and efficient cutting operations. Among the different types of vibratory cutters on the market, twin-blade, horizontal and vertical vibratory cutters are very popular. This article aims to provide an in-depth comparison of these three types of vibrating tools, focusing on their features, advantages, and applications.

Double blade vibrating cutting machine

Twin-blade vibratory cutters are known for their versatility and cutting efficiency. As the name suggests, it consists of two blades that swing simultaneously in opposite directions. This unique design increases cutting speed and improves accuracy. Twin-blade vibratory cutters are particularly suitable for tasks that require high precision, such as cutting complex shapes and patterns on materials such as wood, plastic and metal.

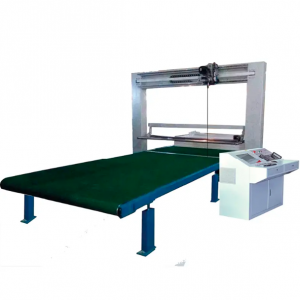

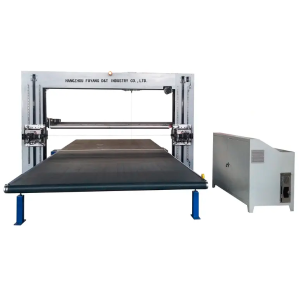

Horizontal vibrating cutter

Horizontal oscillating cutters, also known as oscillating cutters, have a single blade that moves horizontally. This type of vibratory cutter is typically used in applications that require long, continuous cutting strokes, such as trimming large pieces of fabric or cutting thick foam. Horizontal vibration cutters are highly regarded for their stability and ability to produce clean, even cuts.

Vertical vibrating cutter

Compared to horizontal vibration cutters, vertical vibration cutters have blades that move up and down. This type of vibratory cutter is typically used for tasks that involve cutting material vertically, such as trimming wallpaper, cutting slits in cardboard, or cutting thin layers of fabric. Vertical oscillating cutting machines offer excellent control and precision, making them ideal for delicate and complex cutting operations.

Compare and apply

When it comes to cutting efficiency, twin-blade vibratory cutters lead the pack due to their twin-blade design. It allows for faster cutting speeds and reduces the risk of blade jamming. Additionally, the versatility of the dual-blade oscillating cutter makes it suitable for a wide range of applications, including woodworking, metal crafting, and DIY projects. Horizontal vibration cutters, on the other hand, excel in tasks that require continuous and extended cutting strokes. Its stability and ability to handle large and tough materials make it the first choice in industries such as interior decoration, automotive and packaging. Finally, the up-and-down cutting motion of a vertical vibration cutter allows it to efficiently complete tasks involving precise vertical cuts. Commonly used in textile, printing, arts and crafts and other industries.

in conclusion

In summary, double-edged vibrating tools, horizontal vibrating tools, and vertical vibrating tools each have their own unique characteristics and advantages. The dual-blade oscillating cutter provides versatility and increased cutting speed, while the horizontal oscillating cutter provides stability and efficiency during the continuous cutting stroke. Meanwhile, vertical oscillating cutters excel in vertical cutting operations that require precision. Ultimately, the choice of which vibratory cutter to use depends on the specific application and desired cutting results. Nonetheless, these three types of vibrating cutters have undoubtedly revolutionized the cutting industry and continue to play a vital role in various fields.

Post time: Oct-18-2023