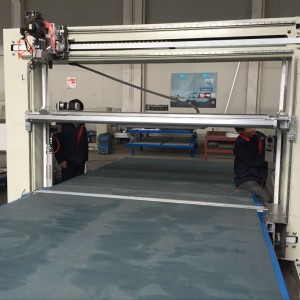

Horizontal Oacillating Cutter

-

Good Price D&T Oscillating Blade Sponge Rigid PU Foam Horizontal Cutting Machine

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

Oscillating Blade Sponge Rigid PU Foam Horizontal Cutting Machine

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

D&T high precision Vib Blade Sponge Rigid PU Foam Horizontal Oacillating Cutter

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

Vibration Blade Sponge Rigid PU Foam Horizontal Oacillating Cutter

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

DTC S2012 Vibration Blade Sponge Rigid Foam Horizontal Oacillating Cutter

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

DTC-S2512 2D CNC Foam Sponge Horizontal Oacillating Cutter

D&T Saw Blade Sponge Foam Oscillating Contour Cutter is a complex shape sponge cutter.

Fast cutting speed, high vibration speed, high efficiency and excellent finished product.

Most importantly, there should be no dust in the cutting process.

All machines are accelerated by the excellent D&T Profiler software.

Optimize your design process to ensure your operators get the best yield from their foam blocks.

-

DTC S2012 Horizontal Oacillating Blade Vibrating Knife Foam Sponge Cutter

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates and cuts at high speed, which makes the working speed faster and the product smoother.

3. Especially dust-free when cutting flexible PU with vibrating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software. This speeds up the design process and allows operators to get the best results from their foam blocks.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

DTC S2512 Horizontal type Oacillating Foam Cutting Machine

The D&T Saw Blade Sponge Foam Contour Cutter is a complex shape sponge cutter.

Fast cutting speed, high vibration speed, high efficiency, good finished product.

Most importantly, there is no dust when cutting.

All machines are accelerated by the excellent D&T Profiler software.

Streamline the design process so operators can get the best yield from foam blocks.

-

DTC S2012 6kw Vibration Cutting Blade Horizontal Oacillating Cuting machine

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).

-

DTC S2512 Horizontal Oacillating Cutter

D&T Saw blade Sponge foam oscillating contour cutter is a complex shape sponge cutter.

Fast cutting speed, high vibration speed, high efficiency, good finished product.

Most importantly, there is no dust in the cutting process.

All machines are accelerated by the excellent D&T Profiler software.

Optimize the design process to enable operators to obtain the best yield from foam blocks.

-

DTC S2012 Horizontal Oacillating Cutter

1. The D&T Oscillating Blade Contour Cutter is a complex shape cutter for soft foam.

2. The blade vibrates at high speed for cutting, the working speed is faster and the product is smoother.

3. Particularly dust-free when cutting flexible PU with an oscillating blade contour cutter.

4. All machines are driven by the excellent D&T Profiler software, which speeds up the design process and enables the operator to get the best output from the foam block.

5. Advantages: PC/IPC control, easy to operate. Workbench: flat workbench, mobile workbench (optional).