Foam cutting is a key process in furniture and upholstery manufacturing, packaging and insulation production, and even art installations. Foam is a versatile material with excellent insulating properties and padding, but it can also be challenging to cut. Thankfully, the introduction of the rotary foam cutter has made foam cutting more precise, efficient and cost-effective. There are three types of rotary foam cutters: horizontal, multi-blade, and vertical. In this article, we'll explore the differences between these types and their applications.

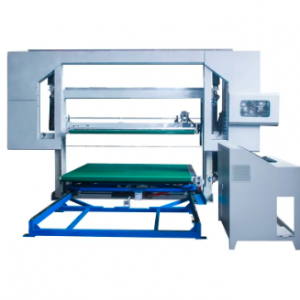

The horizontal rotary foam cutter has a flat cutting table on which the foam is laid and the cutting blade moves horizontally. This type of machine is great for cutting thick, dense foam or making large cuts. The flat cutting table provides stability and the horizontal motion ensures precision and accuracy. This type of machine is often used in upholstery and furniture manufacturing, where blocks of foam need to be cut to specific shapes and sizes.

Multi-edged

A multi-blade rotary foam cutter has multiple vertical blades that move up and down to cut foam. This type of machine is very efficient and can make multiple cuts in one go, increasing production speed. Multi-blade machines are ideal for cutting thin, delicate foam boards, often used in the packaging industry. They can create intricate shapes and patterns, and the foam can also be perforated to create ventilation holes or easy-tear lines.

The vertical rotary foam cutter cuts foam with vertical cutting blades moving up and down. This type of machine is great for cutting foam blocks with uneven surfaces or creating custom shapes and designs. The vertical movement of the blade allows for complex cuts, and the machine can also be programmed to repeat precise cuts. Vertical cutters are often used to produce custom insulation products and artistic foam installations.

Which type is right for you?

The type of rotary foam cutter you choose depends on your specific needs and application. If you are in the upholstery or furniture manufacturing industry, a horizontal cutting machine may be right for you. If you are in the packaging industry and need to quickly cut thin foam boards, a multi-blade machine may be right for you. If you are in the custom insulation or artistic foam installation business, a stand cutter may be just what you need.

Besides the type of machine, there are other factors to consider, such as the size of the foam block you need to cut, the thickness of the foam board, and the complexity of the cut you need. You should also consider the machine's durability and reliability, as well as how easy it is to maintain and repair.

In conclusion

The rotary foam cutting machine has revolutionized the foam cutting industry, making foam cutting more precise, efficient and cost-effective. Three types of rotary foam cutters—horizontal, multi-blade, and vertical—serve different functions and applications. Choosing the right type of machine depends on your specific needs, and you should also consider other factors such as the size and thickness of the foam block and the complexity of the cuts required. With the right rotary foam cutter, you can produce high-quality foam products that meet your customers' needs, while also increasing production speed and efficiency.

Post time: May-26-2023