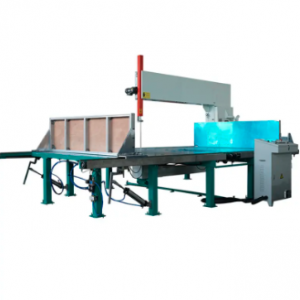

Vertical foam cutters are invaluable tools in various industries such as furniture, packaging and automotive. It cuts foam precisely, efficiently and smoothly. Regular maintenance is essential to keep machines in top working condition and ensure their longevity. In this article, we discuss some key maintenance tips for vertical foam cutters.

1. Keep the machine clean: Regular cleaning is important to remove any dust, debris or foam particles that may have accumulated on the machine. Use a soft cloth or brush to clean the cutting table, blades, and other parts. Avoid harsh chemicals as they may damage machine surfaces.

2. Lubricate moving parts: Lubrication is essential to maintain the smooth operation of the machine. Check the manufacturer's instructions to determine the lubrication point and use the recommended lubricant. Apply lubricant to bearings, guides and other moving parts to reduce friction and ensure proper function.

3. Check the blade: the blade is the key component of the vertical foam cutting machine. Check the blade regularly for any signs of wear or damage. If the blade is dull or chipped, it may not cut foam effectively. If necessary, replace the blade and make sure it is properly aligned and tightened securely.

4. Adjust cutting wire or blade tension: Over time, the cutting wire or blade tension may need to be adjusted. Incorrect tension may result in uneven cuts or foam damage. Consult machine manual to determine proper tension and make necessary adjustments.

5. Check electrical connections: Electrical connections play a vital role in the function of the machine. Check the wiring, connectors, and power supply regularly to make sure there are no loose connections or frayed wires. Any problems should be resolved immediately by a qualified technician.

6. Perform routine maintenance checks: Create a regular maintenance schedule for your vertical foam cutter. This should include tasks such as checking belts, gears and motors for signs of wear or damage. Also, check safety features such as emergency stop buttons and safety guards to make sure they are in working order.

7. Train the Operator: Properly trained operators are critical to the safe and efficient operation of a vertical foam cutter. Provide training for your employees on how to properly use the machine, including its maintenance and safety procedures. Operators are encouraged to report any problems or abnormalities discovered during operation.

By following these maintenance tips, you can keep your vertical foam cutter running smoothly and efficiently, minimizing downtime and maximizing productivity. Regular maintenance not only prolongs the life of your machine, but also improves the quality of your foam cuts. Remember to consult the manufacturer's guidelines and seek professional help if needed. With proper care and maintenance, your vertical foam cutter will continue to be a reliable asset to your business.

Post time: Jun-28-2023