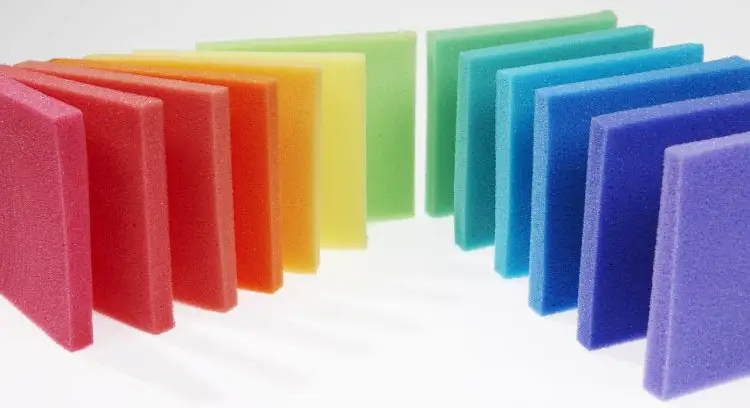

Polyurethane soft foam series products mainly include block, continuous, sponge, high resilience foam (HR), self-skin foam, slow resilience foam, microporous foam and semi-rigid energy-absorbing foam. This type of foam still accounts for about 50% of the total polyurethane product. There are a wide variety of products and the scope of application is constantly expanding, and they have been involved in various fields of the national economy: household appliances, automobiles, home improvement, furniture, trains, ships, aerospace and many other fields. Since the advent of PU soft foam in the 1950s, especially after entering the 21st century, technology, variety, and product output have all made leaps. Highlights include: environmentally friendly PU soft foam, namely green polyurethane products; low VOC value PU soft foam; low atomization PU soft foam; full water PU soft foam; full MDI series soft foam; flame retardant, low smoke, full MDI series foam ; New additives such as reactive polymer catalysts, stabilizers, flame retardants and antioxidants; polyols with low unsaturation and low monoalcohol content; ultra-low density PU flexible foam with excellent physical properties; low resonance frequency, Low-transfer PU soft foam; polycarbonate diol, polyε-caprolactone polyol, polybutadiene diol, polytetrahydrofuran and other special polyols; liquid CO2 foaming technology, negative pressure foaming technology, etc. In short, the emergence of new varieties and new technologies has promoted the further development of PU soft foam.

Foaming principle

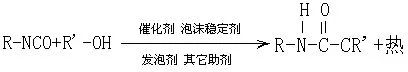

In order to synthesize the ideal PU soft foam that meets the requirements, it is necessary to understand the chemical reaction principle of the foam system in order to select the appropriate main and auxiliary raw materials and manufacturing processes. The development of the polyurethane industry is no longer an imitation stage, but is realized through the raw material structure and synthesis process according to the performance requirements of the final product. Polyurethane foam participates in chemical changes during the synthesis process, and the factors affecting the structural properties of the foam are complex, not only involving the chemical reaction of isocyanate, polyether (ester) alcohol and water, but also the colloid chemistry of foaming. Chemical reactions include chain extension, foaming and cross-linked. It also affects the structure, function and molecular weight of the substances involved in the reaction. The general reaction for the synthesis of polyurethane foam can be expressed by the following formula:

Post time: Sep-06-2022