In the highly competitive world of manufacturing and processing, companies are always looking for innovative solutions to improve efficiency and productivity. One technological advancement that is making waves in the industry is the vertical vibration cutter. This cutting-edge tool is revolutionizing the way materials are processed and brings a wide range of benefits to businesses across a variety of industries.

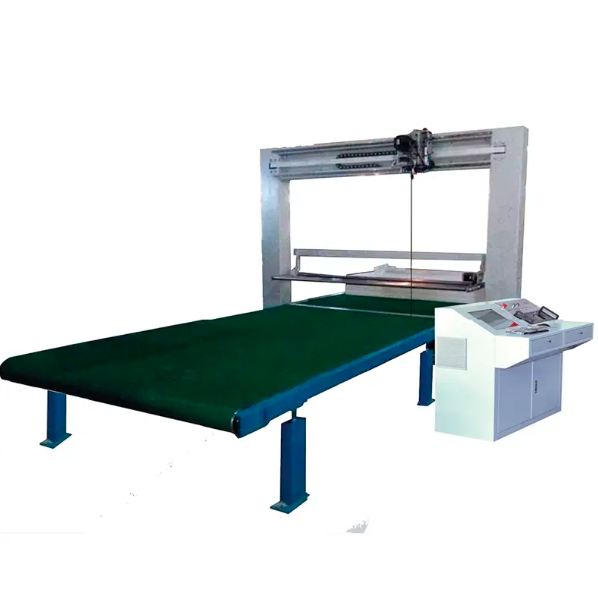

The vertical vibration cutter is a versatile, powerful cutting machine capable of cutting, trimming and shaping a variety of materials, including foam, rubber, cardboard and other non-metallic substances. It utilizes vertical oscillating motion to achieve precise, clean cuts, making it an ideal tool for industries such as packaging, automotive, aerospace and furniture manufacturing.

One of the main advantages of vertical oscillating cutters is their versatility. It can be easily adapted to different cutting requirements, making it suitable for a wide range of applications. Whether you need to cut complex shapes, create custom packaging or trim materials to precise dimensions, a vertical oscillation cutter can handle it with ease. This flexibility enables companies to streamline production processes and meet market demands more efficiently.

Another significant advantage of vertical vibratory cutters is their efficiency. The cutting blade's oscillating motion ensures a smooth and consistent cutting action for a clean, accurate cut every time. This eliminates the need for manual pruning or grooming, saving businesses time and labor costs. In addition, the machine's high-speed cutting capabilities can significantly increase output, allowing companies to meet tight deadlines and complete large orders without compromising quality.

Additionally, vertical vibration cutters are designed to increase workplace safety. Its advanced features and automation reduce the risk of accidents and injuries associated with manual cutting processes. Additionally, the machine is equipped with safety sensors and emergency stop mechanisms to ensure a safe working environment for employees. By investing in a vertical vibratory cutter, businesses can demonstrate their commitment to workplace safety and compliance with industry regulations.

In addition to technical capabilities, vertical vibration cutters also bring cost-saving benefits to businesses. By streamlining the cutting process and minimizing material waste, the machine can help reduce operating costs and improve resource utilization. Additionally, its durable construction and low maintenance requirements make it a cost-effective investment in the long run. With the help of vertical vibration cutting machines, companies can achieve higher productivity and lower production costs, ultimately improving profitability and market competitiveness.

All in all, vertical vibration cutters are a game changer for businesses looking to optimize their cutting processes and achieve better results. Its versatility, efficiency, safety features and cost-saving advantages make it a valuable asset to industries that rely on precise and high-quality cutting operations. By integrating vertical vibration cutters into their operations, businesses can stay ahead of the competition and succeed in today's dynamic business environment.

Post time: Jan-24-2024