In today's fast-moving world, technology has revolutionized every aspect of our lives. When it comes to vertical cutters, there are two main options: automatic vertical cutters and manual vertical cutters. Each has its pros and cons, so deciding between them is crucial. In this blog post, we'll explore the key differences between these two types of vertical cutters and help you decide which one is best for your specific needs.

Automatic vertical cutting machine:

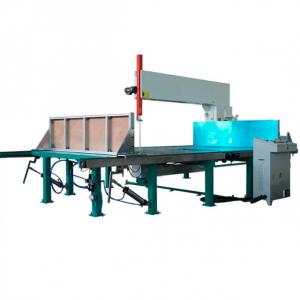

The automatic vertical cutter is powered by electricity and designed to simplify the cutting process. Packed with advanced features, these machines are ideal for mass production and businesses with high-volume cutting requirements. Here are some advantages of automatic vertical cutting machines:

1. Efficiency and precision: With advanced technology, the automatic vertical cutting machine improves cutting speed and precision. They are equipped with programmable cutting modes for consistent, accurate cuts every time. This feature ensures uniformity of the final product and minimizes waste.

2. Increased productivity: Thanks to automation, these cutting machines can perform multiple cutting tasks at the same time. This significantly increases productivity, allowing you to process more material in less time. Automatic vertical cutters are ideal for industries such as paper, packaging and textiles.

3. Ease of use: Despite its advanced features, the automatic vertical cutter is designed to be easy to use. Once programmed, they can perform cutting tasks with minimal human intervention. While the machine is efficiently handling the cutting process, the operator can focus on other important tasks.

Manual Vertical Cutter:

Manual vertical cutters, on the other hand, are powered by the operator and require manual adjustments for each cutting task. Although they lack the automation features of their counterparts, manual vertical cutters offer unique advantages that may be beneficial for certain applications:

1. Versatility: Compared with automatic vertical cutters, manual vertical cutters offer greater flexibility as they can be adapted to different materials and cutting requirements. Operators gain greater control over the cutting process, allowing for on-the-fly customization and adjustments.

2. Cost-effective: Manual vertical cutters are usually less expensive than automatic cutters. If your business has limited cutting requirements or is just starting out, investing in a manual vertical cutter could be a cost-effective solution.

3. Skill development: Operating a manual vertical cutter requires precision and skill. For certain industries, such as crafts or custom products, manual control over the cutting process ensures personalization and attention to detail. It also promotes skill development among employees, fostering a sense of pride and craftsmanship.

in conclusion:

Deciding between automatic and manual vertical cutters ultimately comes down to your specific needs and priorities. If you have high-volume production requirements and prioritize speed, precision and efficiency, an automatic vertical cutting machine is recommended. On the other hand, if you need flexibility, customization and cost-effectiveness, a manual vertical cutter may be the best fit.

Before making a decision, consider your production needs, budget, materials, and the level of control you need over the cutting process. By understanding the advantages and limitations of each type of vertical cutting machine, you will be able to make an informed choice that meets your business goals.

Keep in mind that the choice between an automatic vertical cutter and a manual vertical cutter is not necessarily a good one or a bad one. It's about finding the option that best suits your unique needs and priorities.

Post time: Sep-06-2023