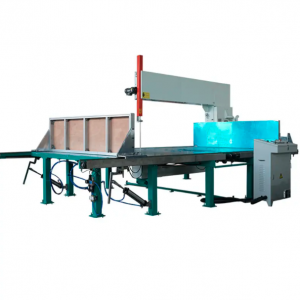

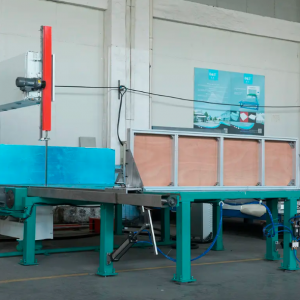

In today's fast-paced world, automation plays an important role in streamlining and optimizing tasks across industries. One of these innovations is the automatic vertical cutting machine, which has revolutionized the cutting process in packaging, printing and other industries. This article aims to illustrate the benefits of using an automatic vertical cutting machine, highlighting its impact on efficiency, precision and safety.

One of the main advantages of automatic vertical cutters is their ability to increase the efficiency of the cutting process. By automating repetitive tasks, the machine significantly reduces the time and effort required to accurately cut materials. With its sophisticated software and advanced controls, the automatic vertical cutting machine can accurately execute a variety of cutting patterns and designs, streamlining the production process. This increase in efficiency enables businesses to meet tight deadlines, increase productivity, and ultimately enhance their competitiveness in the marketplace.

Precision is another major advantage offered by automatic vertical cutters. Unlike manual cutting methods where human error is inevitable, these machines are designed to provide consistently accurate cutting results regardless of the complexity of the pattern or material. Whether cutting fabric, plastic, foam or paper, automatic vertical cutting machines ensure high precision, reduce material waste and minimize rework. This precise cutting capability not only saves resources but also helps improve the quality of the final product, thereby increasing customer satisfaction and loyalty.

Safety is a key consideration during any cutting process, as accidents and injuries can occur if proper precautions are not taken. Automatic vertical cutters solve this problem by incorporating a variety of safety features that prioritize the operator's well-being. These features may include safety guards, emergency stop buttons and sensors that detect any obstructions during the cutting process. Additionally, the automated aspect of the machine eliminates the need for humans to come into direct contact with the sharp blades, significantly reducing the risk of accidents. By ensuring a safer working environment, companies can protect their employees and avoid any potential legal liability.

The versatility of automatic vertical cutters is another aspect that sets them apart from traditional cutting methods. These machines can handle a variety of materials such as textiles, foams, plastics, composites, and more. Additionally, they can accommodate materials of different sizes, shapes and thicknesses, allowing greater flexibility in production. This adaptability is particularly beneficial for businesses that handle multiple product lines or frequently change cutting requirements. By investing in automatic vertical cutting machines, companies can meet different customer needs and expand their product range without the need for additional machinery.

Furthermore, automatic vertical cutting machines are known for their user-friendly operation and easy integration. Manufacturers understand the importance of providing intuitive interfaces and controls that allow operators to effectively manipulate the machine's functions without requiring extensive training. Additionally, these machines can be seamlessly integrated into existing production lines, reducing disruption and ensuring smooth workflow. This streamlined integration process further supports businesses in maximizing return on investment and minimizing downtime or delays.

In summary, automatic vertical cutting machines offer several significant advantages to industries that require precise and efficient cutting processes. From increasing efficiency and precision to ensuring safety and promoting versatility, this automation innovation revolutionizes the way materials are cut. As companies strive to improve productivity and product quality, automatic vertical cutters are proving to be a valuable asset in achieving these goals.

Post time: Nov-22-2023