ODM High Quality Foam Pipe Insulation Cutter Supplier – DTC-R2012H Horizontal Type – D&T Industry

ODM High Quality Foam Pipe Insulation Cutter Supplier – DTC-R2012H Horizontal Type – D&T Industry Detail:

Basic Information

| Place of Origin: | China | |||

| Brand Name: | D&T | |||

| Certification: | CE | |||

| Model Number: | DTC-R2012V5 | |||

| Minimum Order Quantity: | 1 set | |||

| Price: | USD30000 – 80000 / set | |||

| Packaging Details: | Film + wooden box | |||

| Delivery Time: | 40 working days | |||

| Payment Terms: | L/C, T/T,paypal | |||

| Supply Ability: | 20 sets / month | |||

| Max.Product Size: | L3000*W2200*H1200mm | Control System: | Industrial Computer+Window XP | |

| Cutting Speed: | 0-40m/min | Software: | D&T Revolving Profiler | |

| Tolerance: | ±5mm | Total Power: | 5kw,380V,50Hz | |

| Overall Weight: | 2700kg | Overall Dimension: | L6200*W5630*3200mm | |

| High Light: | foam cutting equipment,polyurethane cutting machine | |||

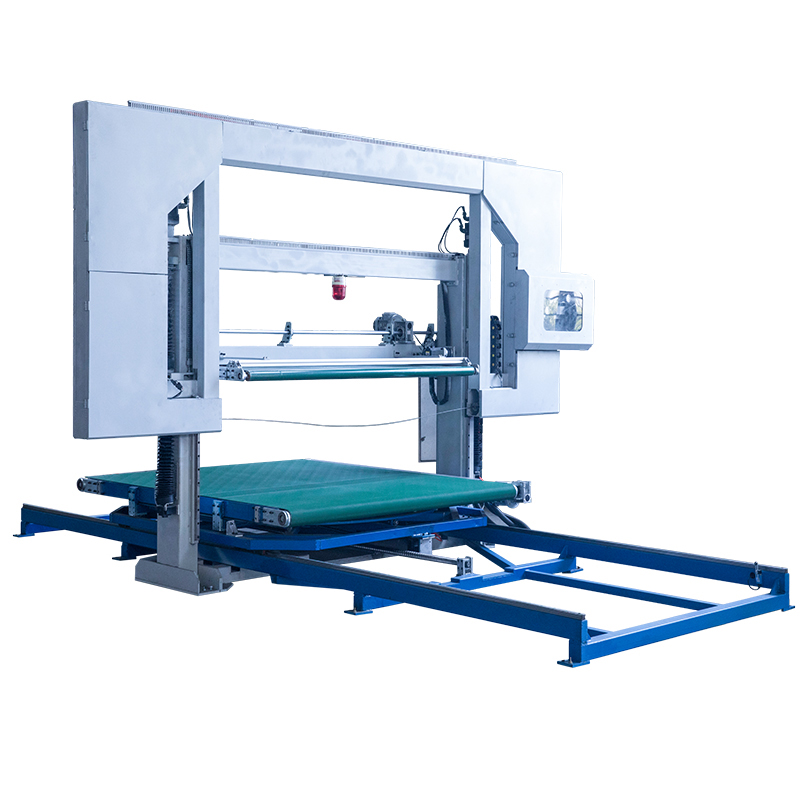

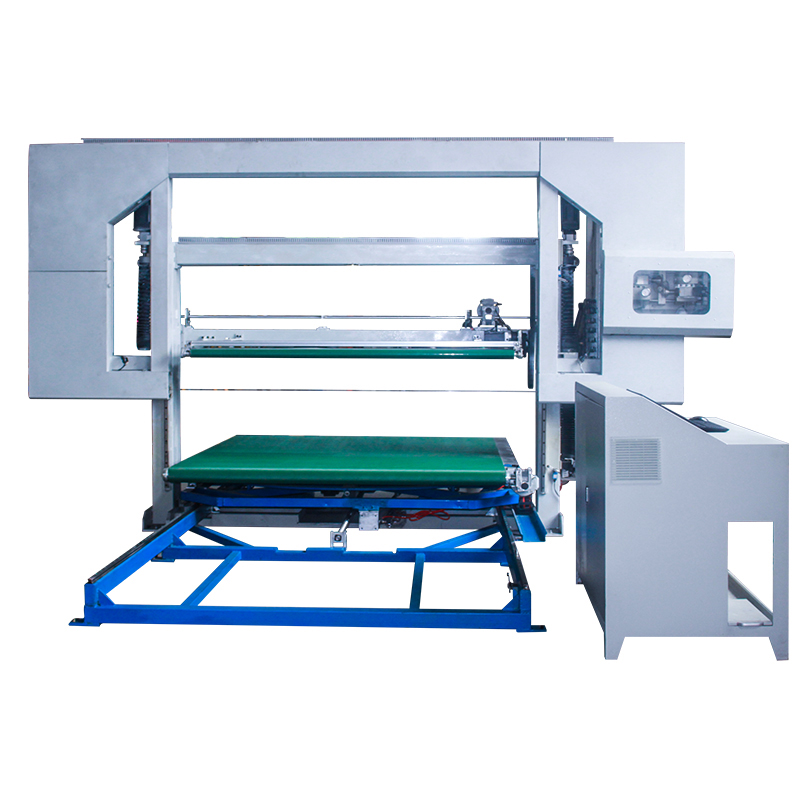

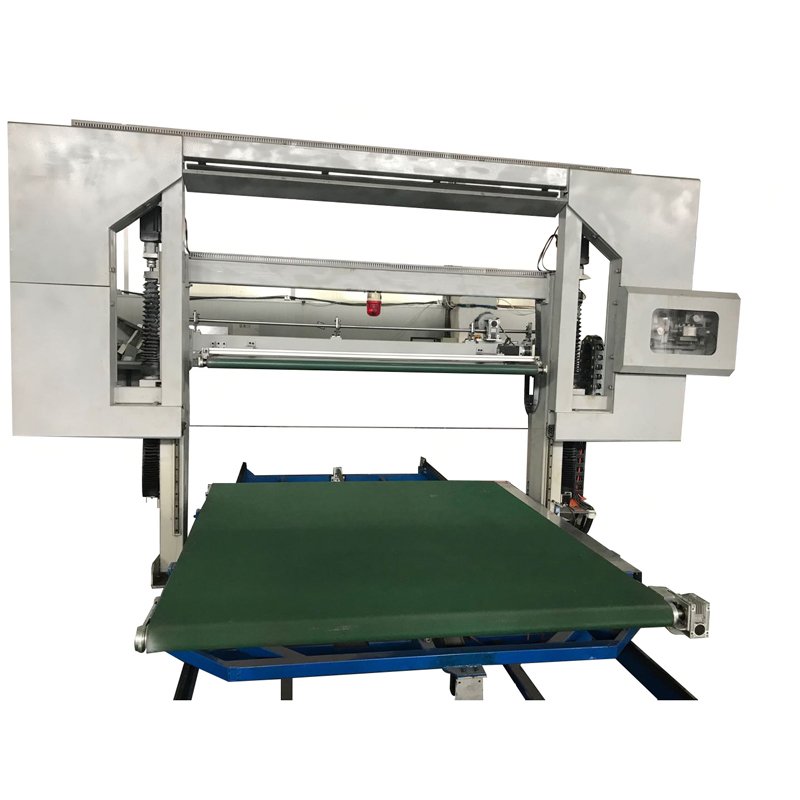

D&T Loop knife Cutting Machine Sponge Machine pu foam cutter Horizontal Revolving Contour Cutter

Revolving Contour Cutter

| Model | DTC-R2012V | DTC-R2012V5 | DTC-R2012H |

| Max. Product Size | L2800*W2200*1000mm | L3000*W2200*H1200mm | L2800*W2200*H1000mm |

| Control System | Industrial Computer+Window XP | Industrial Computer+Window XP | Industrial Computer+Window XP |

| Software | D&T revolving Profiler | D&T revolving Profiler | D&T revolving Profiler |

| Cutting Speed | 0~40m/min(Adjustable) | 0~40m/min(Adjustable) | 0~40m/min(Adjustable) |

| Tolerance | ±5mm | ±5mm | ±5mm |

| Total Power | 5kw,380V,50Hz | 5kw,380V,50Hz | 5kw,380V,50Hz |

| Overall Weight | 2500kg | 2700kg | 2500kg |

| Overall Dimension | L6000*W5630*3000mm | L6200*W5630*3200mm | L6000*W5630*3000mm |

Cutting Method: Loop Knife Revolving CNC Cutting Machine

Can Cut material: sponge, sponge laminated materials

Advantage: Max. Cutting Speed: 80m/min

The machine consists of

1). Cutting Frame. It is a Steel welded frame with a moveable frame to bring the knife system go up and down. There are four flying wheels on the moveable. One is driver by motor and other threes are passive. Four wheel be a circle to bring the loop knife to run.

There are two blade turning units on the moveable frame also. It will turn the knife to keep the knife shaper point to the tangent to the drawing.

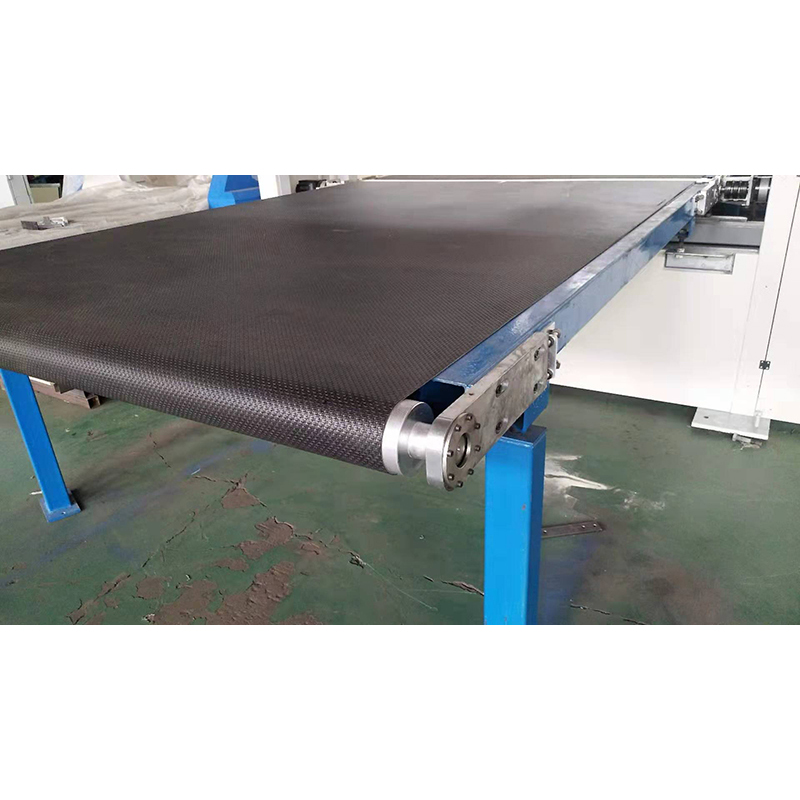

2). Working table.

3). Control Cabinet. It included Motion and 4 axis control systems. The motion control system includes a high-quality D&T 4 Axis Motion Controller, Stepping/servo drivers, and control system. It also includes DXF software for simple and easy file conversion.

There is one Evoc Industrial computer with monitor for human communication and program design.

Specifications

1. Advanced automatic computer foam contour cutting machine.

2. The foam can be cut into any two-dimensional complex shape.

3. Easy to control

This foam cutter is state of the art,

Fully automatic computer foam contour cutting machine,

It can cut various shapes by computer system.

1. This eva foam contour cutting machine is operated by computer

And use CAD software to design the shape of the foam block.

Use foam blocks and

Significant savings in raw material (foam block) costs.

2. In addition to CAD software, we also designed another drawing software

Provided by our engineers, it is very easy to use.

Operators only need to receive simple computer knowledge training.

3. This CNC contour cutting machine is equipped with wireless

Remote control makes the operation more user-friendly.

4. Equipped with high-precision servo system;

Fast cutting speed and accurate cutting;

Thereby improving work efficiency.

5. 85% of the dust will be collected

The bag has low noise during the cutting process.

6. Operating system: Windows XP

7. Design software: Auto CAD/self-developed CNC operating software.

8. Cutting software: foam cutting control system

Application

Efficient, economic and practical sponge CNC cutting machine can be used for various types of sponge, PVA, EPE, EPS, phenolic and other materials processing, has been widely used in insulation, packaging, decorative products, such as PU and foam slice, shape processing industries.

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for ODM High Quality Foam Pipe Insulation Cutter Supplier – DTC-R2012H Horizontal Type – D&T Industry , The product will supply to all over the world, such as: Jamaica, Macedonia, Estonia, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.