Famous Best Styrofoam Cutting Wand Supplier – DTC-R2012H 5kw Horizontal Type Sponge Cutting machine – D&T Industry

Famous Best Styrofoam Cutting Wand Supplier – DTC-R2012H 5kw Horizontal Type Sponge Cutting machine – D&T Industry Detail:

Basic Information

| Place of Origin: | China | |||

| Brand Name: | D&T | |||

| Certification: | CE | |||

| Model Number: | DTC-R2012V5 | |||

| Minimum Order Quantity: | 1 set | |||

| Price: | USD30000 – 80000 / set | |||

| Packaging Details: | Film + wooden box | |||

| Delivery Time: | 40 working days | |||

| Payment Terms: | L/C, T/T,paypal | |||

| Supply Ability: | 20 sets / month | |||

| Max.Product Size: | L3000*W2200*H1200mm | Control System: | Industrial Computer+Window XP | |

| Cutting Speed: | 0-40m/min | Software: | D&T Revolving Profiler | |

| Tolerance: | ±5mm | Total Power: | 5kw,380V,50Hz | |

| Overall Weight: | 2700kg | Overall Dimension: | L6200*W5630*3200mm | |

| High Light: | foam cutting equipment,polyurethane cutting machine | |||

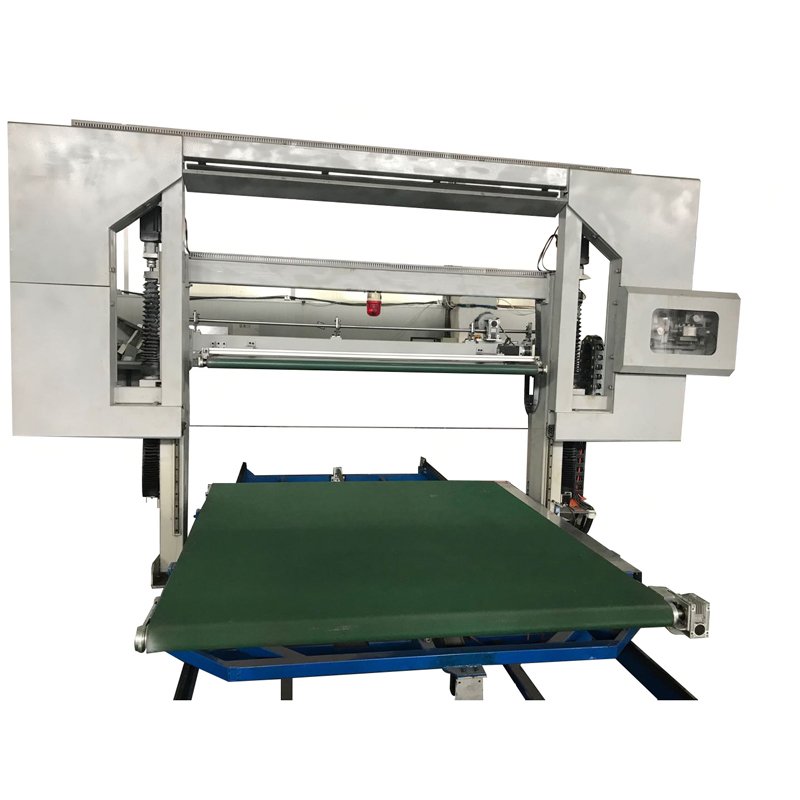

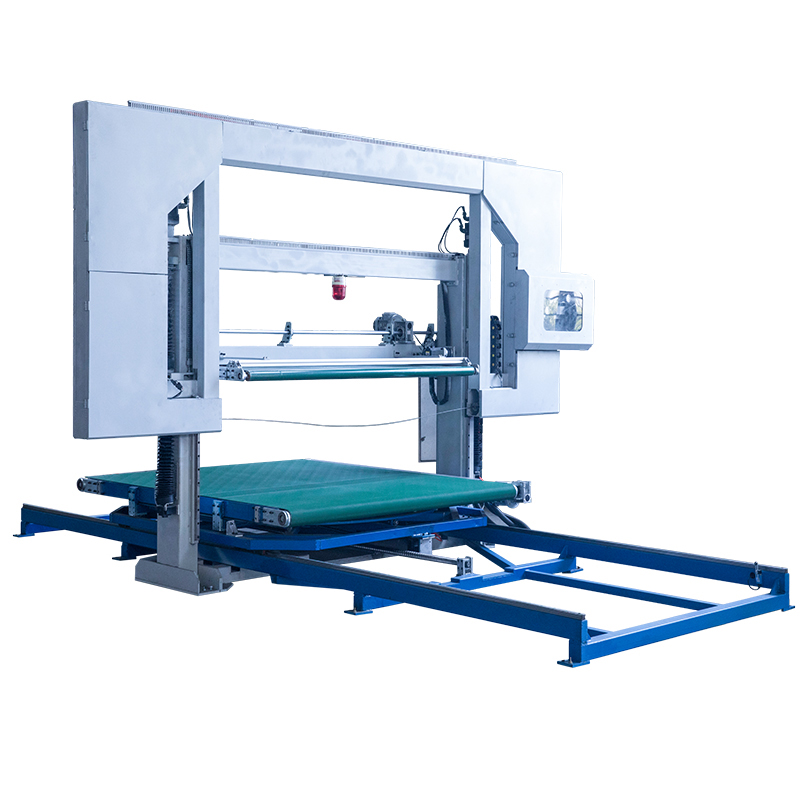

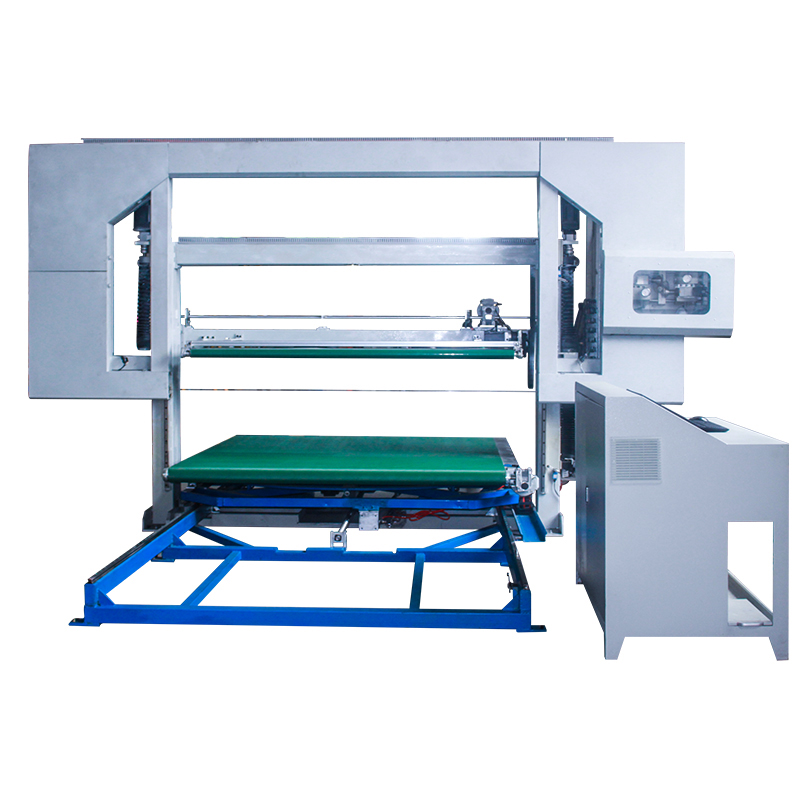

D&T Loop knife Cutting Machine Sponge Machine pu foam cutter Horizontal Revolving Contour Cutter

Revolving Contour Cutter

| Model | DTC-R2012V | DTC-R2012V5 | DTC-R2012H |

| Max. Product Size | L2800*W2200*1000mm | L3000*W2200*H1200mm | L2800*W2200*H1000mm |

| Control System | Industrial Computer+Window XP | Industrial Computer+Window XP | Industrial Computer+Window XP |

| Software | D&T revolving Profiler | D&T revolving Profiler | D&T revolving Profiler |

| Cutting Speed | 0~40m/min(Adjustable) | 0~40m/min(Adjustable) | 0~40m/min(Adjustable) |

| Tolerance | ±5mm | ±5mm | ±5mm |

| Total Power | 5kw,380V,50Hz | 5kw,380V,50Hz | 5kw,380V,50Hz |

| Overall Weight | 2500kg | 2700kg | 2500kg |

| Overall Dimension | L6000*W5630*3000mm | L6200*W5630*3200mm | L6000*W5630*3000mm |

Cutting Method: Loop Knife Revolving CNC Cutting Machine

Can Cut material: sponge, sponge laminated materials

Advantage: Max. Cutting Speed: 80m/min

The machine consists of

1). cutting frame. It is a steel welded frame with a movable frame for raising and lowering the knife system. The moving part has four flying wheels. One is motorized and the other three are passive. Four wheels run his knives looping in a circle.

The moving frame also has two blade rotation units. Rotate the knife so that the point of the knife shaper touches the drawing.

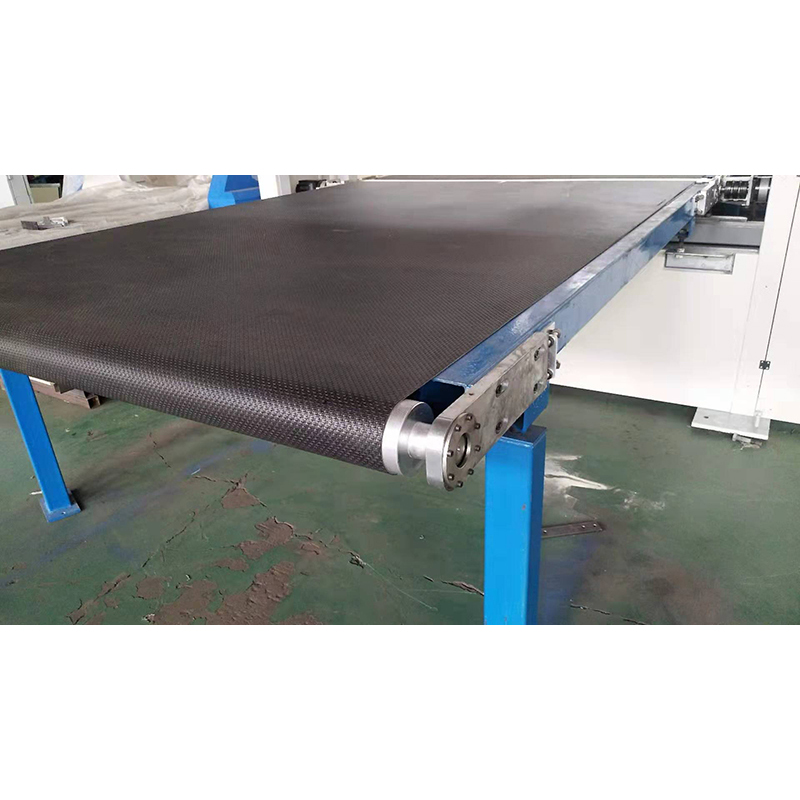

2). Workbench.

3). control cabinet. This included motion and her four-axis control system. Motion Her Controls Her systems include high quality Her D&T 4-axis motion controllers, stepper/servo Her drivers, and control systems. Also includes his-her-DXF-her software for simple and easy file conversion.

She has one Evoc industrial computer with a monitor for human communication and program design.

specification

1. Advanced automatic computer foam contour cutting machine.

2. The form can be cut into any her 2D complex shape.

3. Easy to control

This foam cutter is cutting edge,

fully automatic computer foam contour cutting machine,

A variety of shapes can be cut by the computer system.

1. This evafoam contour cutting machine is computer operated

Design the shape of form his block using CAD software.

use foam block

Significant savings in raw material (foam block) costs.

2. In addition to CAD software, we also designed another drawing software.

It is provided by our engineers and is very easy to use.

Operators only need to be trained in basic computer knowledge.

3. This CNC contour cutting machine is equipped with wireless

Remote control makes operation more user-friendly.

4. Equipped with high-precision servo system.

Fast cutting speed and precise cutting;

This improves work efficiency.

5. Collect 85% dust

The bag has low noise during the cutting process.

6. Operating System: Windows XP

7. Design software: Auto CAD/self-developed his CNC operating software.

8. Cutting software: foam cutting control system

application

Efficient, economical and practical sponge CNC cutting machine can be used for various types of sponge, PVA, EPE, EPS, phenolic and other material processing, insulation, packaging, decoration of PU and foam slicing, etc. increase. Widely used in product, shape processing industry.

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Famous Best Styrofoam Cutting Wand Supplier – DTC-R2012H 5kw Horizontal Type Sponge Cutting machine – D&T Industry , The product will supply to all over the world, such as: Casablanca, Swedish, Oslo, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.