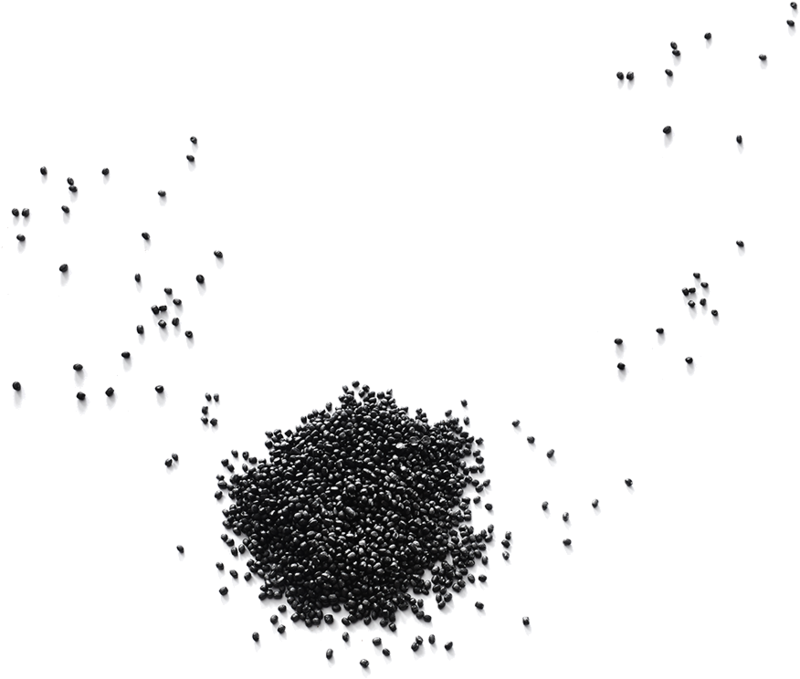

Expanded polypropylene (EPP for short) is an ultra-light, closed-cell thermoplastic foam particle based on polypropylene foam. It is black, pink or white, and the diameter is generally between φ2 and 7mm. EPP beads are composed of two phases, solid and gas. Usually, the solid phase only accounts for 2% to 10% of the total weight, and the rest is gas. The minimum density range is 20-200 kg/m3. Specifically, the weight of EPP is lighter than that of polyurethane foam under the same energy-absorbing effect. Therefore, the foam parts made of EPP beads are light in weight, have good heat resistance, good cushioning properties and excellent mechanical properties, and are 100% degradable and recyclable. All these advantages make EPP one of the most widely used materials in many fields, in every aspect of our life:

In the automotive field, EPP is the best solution to achieve lightweight components, such as bumpers, automotive A-pillar trims, automotive side shock cores, automotive door shock cores, advanced safety car seats, tool boxes, trunks, armrests, Foamed polypropylene material can be used for parts such as bottom plate, sun visor and instrument panel. Statistical data: At present, the average amount of plastic used in automobiles is 100-130kg/vehicle, of which the application of foamed polypropylene is 4-6kg/vehicle, which can reduce the weight of automobiles by up to 10%.

In the field of packaging, reusable packaging and transportation containers made of EPP have the characteristics of heat preservation, heat resistance, corrosion resistance, insulation, long service life, etc., do not contain volatile organic compounds, do not contain single substances that are harmful to the ozone layer or heavy metals Material packaging, can be digested after heating, 100% environmentally friendly. Whether it is precision electronic components, or the transportation of fruits, frozen meat, ice cream and other foods, expanded polypropylene foam can be used. According to the BASF stress level test, EPP can regularly achieve 100 or more shipping cycles, which greatly saves materials and reduces packaging costs.

Post time: Aug-31-2022